Mine wastes: Environmental impacts and resource potential

Within the last hour, you may have looked at your mobile phone, used a computer, driven your car, or used electricity. Perhaps without realising it, you have made use of mined materials such as metals, industrial minerals or energy resources. Mining has been carried out since prehistory, as humans have needed, and still need, these resources to make tools, buildings, machinery, infrastructure, artworks and other goods. Mining also provides jobs, contributes to GDP, supports cultural development and provides scientific knowledge. Mining is a global activity: Many countries currently support an industry and gain economic benefit from it, and even countries who no longer have a mining industry have had one in the past.

Some of the materials extracted through mining, including industrial minerals like gypsum, are fully utilised. Others, like metals, only form a small proportion of the material extracted. This means that a large percentage of the extracted materials are wastes. Because most high-grade ores have now been exploited through millennia of mining, contemporary ores are much lower grade. As a result, we are now producing more waste from mining than ever before. But what is this waste? Should we be concerned about it? And can we make use of it?

What are mine wastes?

Mine wastes are defined as “materials originating, accumulating and present at mine sites, which are unwanted and have no current economic value” (1). They can occur in gaseous, solid and liquid form. Gaseous wastes include compounds produced during smelting or other processing, such as sulfur dioxide. Solid mine wastes include waste rock, tailings, slag, metallurgical materials, and contaminated river sediments. Most commonly found are tailings, which are fine-grained mixtures of crushed rock and processing fluids produced in mills, washeries, or concentrators that remain after the extracted ores are processed (2). Tailings are commonly stored as slurries in tailings storage facilities also known as tailings dams.

Some of the materials extracted through mining, including industrial minerals like gypsum, are fully utilised. Others, like metals, only form a small proportion of the material extracted. This means that a large percentage of the extracted materials are wastes. Because most high-grade ores have now been exploited through millennia of mining, contemporary ores are much lower grade. As a result, we are now producing more waste from mining than ever before. But what is this waste? Should we be concerned about it? And can we make use of it?

What are mine wastes?

Mine wastes are defined as “materials originating, accumulating and present at mine sites, which are unwanted and have no current economic value” (1). They can occur in gaseous, solid and liquid form. Gaseous wastes include compounds produced during smelting or other processing, such as sulfur dioxide. Solid mine wastes include waste rock, tailings, slag, metallurgical materials, and contaminated river sediments. Most commonly found are tailings, which are fine-grained mixtures of crushed rock and processing fluids produced in mills, washeries, or concentrators that remain after the extracted ores are processed (2). Tailings are commonly stored as slurries in tailings storage facilities also known as tailings dams.

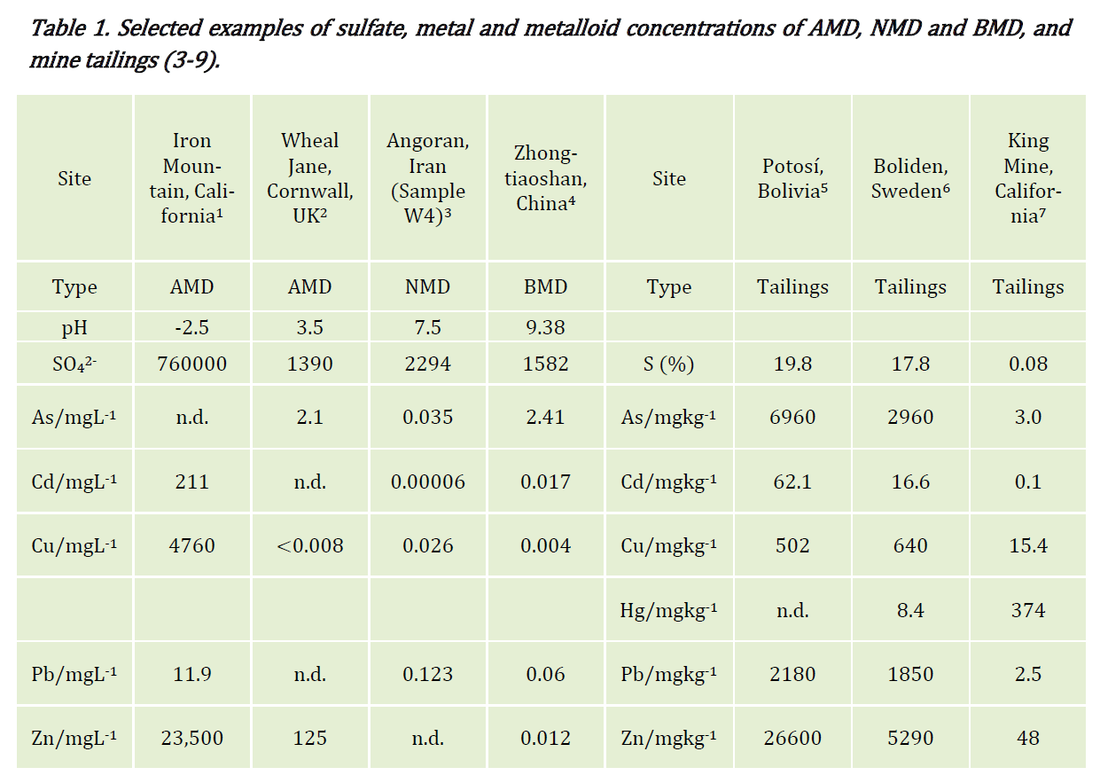

Liquid mine wastes include processing compounds that are not reused, and waters that are generated from the reaction of solid mine wastes with meteoric (precipitated) waters. The latter, called ‘drainage’, are classified into three major types according to their pH. The most common and deleterious of these is ‘acid mine drainage’ (AMD) (Figure 1a), which exhibits pH values from –3.5 to 5 (3). The pH of circum-neutral mine drainage (CMD) varies between 6 and 8, and that of basic mine drainage (BMD) varies between 9 and 12. AMD, CMD and BMD can be radioactive, corrosive and highly toxic (3). The toxicity arises because the waters, like solid mine wastes described above, can contain elevated concentrations of metals and metalloids that, if ingested or inhaled by organisms, can cause lethal or sub-lethal effects. Examples are shown in Table 1. Metal and metalloid concentrations of AMD waters are generally higher than those of NMD or BMD waters, although BMD waters often contain high concentrations of metalloids that form anions (e.g. As). Concentrations are variable, depending on the ore mineralogy and degree of neutralisation that takes place for AMD and BMD. For solid mine wastes such as tailings, metal and metalloid concentrations also vary depending on the geology of the ore deposit, and type of economic commodity that has been extracted. Tailings can either have elevated concentrations of a suite of metals and metalloids (e.g. Potosí, Bolivia, Table 1), or one or two metals (e.g. King Mine, California, Table 1).

Environmental impacts of mine wastes

Legacy and contemporary mine wastes have had and still have negative impacts on water and soil quality, and ecosystem and human health (2, 10). These impacts generally arise from the elevated concentrations of potentially toxic metals and metalloids (e.g. Table 1) that contaminate waters and soils, and cause negative health impacts such as poisoning and cancers (11). Other negative impacts include increased sedimentation of rivers and estuaries due to large inputs of wastes to these environments (12), and tailings dam failures (2). The latter are catastrophic events in which the embankment walls fail, and large volumes of tailings solids and interstitial water are released suddenly into river catchments, causing erosion, deposition, destruction of infrastructure and ecosystems and, in some cases, death. Recent analysis has suggested that the severity of tailings dam failures is increasing as mining of lower grade deposits generates higher amounts of tailings, and larger dams are being built to accommodate them (13).

A new frontier: mine wastes as resources

Significant global effort is being made to reduce the negative impacts of mine wastes. Part of this effort is directed towards viewing mine wastes as resources. This includes recovering economic metals from tailings (14) and AMD (15), using wastes to manufacture products such as bricks, cement, floor tiles and pigments (16), sequestering CO2 in ultramafic wastes (high alkaline igneous rocks (17)), and adding wastes to soils as amendments (16).

Mine wastes have other value. They are unparalleled natural laboratories for studying extreme conditions of pH, metal and metalloid concentrations and bacteria and other organisms that are adapted to these. Metallophyte plants have developed on mine wastes globally; these stabilise the wastes and, if they sequester metals and metalloids in their roots, prevent further accumulation up the food chain by grazers on their roots. The 80 km long AMD Río Tinto, SW Spain, is used as an analogue site for Martian research (18).

Research gaps

Over the past two decades, we have developed a good basic understanding of the environmental impacts and resource potential of mine wastes. There is more to do to better understand the speciation of metals and metalloids, how they are taken up in minerals and biota, the role of microorganisms in their release and storage in the environment, their global health impacts and the ways in which we can recycle, reuse and remediate them. We are now mining ‘green technology’, or ‘critical raw materials’, in much greater quantities than before to meet the demand for a low carbon economy, and there is much work to do to better understand and manage the wastes produced.

Legacy and contemporary mine wastes have had and still have negative impacts on water and soil quality, and ecosystem and human health (2, 10). These impacts generally arise from the elevated concentrations of potentially toxic metals and metalloids (e.g. Table 1) that contaminate waters and soils, and cause negative health impacts such as poisoning and cancers (11). Other negative impacts include increased sedimentation of rivers and estuaries due to large inputs of wastes to these environments (12), and tailings dam failures (2). The latter are catastrophic events in which the embankment walls fail, and large volumes of tailings solids and interstitial water are released suddenly into river catchments, causing erosion, deposition, destruction of infrastructure and ecosystems and, in some cases, death. Recent analysis has suggested that the severity of tailings dam failures is increasing as mining of lower grade deposits generates higher amounts of tailings, and larger dams are being built to accommodate them (13).

A new frontier: mine wastes as resources

Significant global effort is being made to reduce the negative impacts of mine wastes. Part of this effort is directed towards viewing mine wastes as resources. This includes recovering economic metals from tailings (14) and AMD (15), using wastes to manufacture products such as bricks, cement, floor tiles and pigments (16), sequestering CO2 in ultramafic wastes (high alkaline igneous rocks (17)), and adding wastes to soils as amendments (16).

Mine wastes have other value. They are unparalleled natural laboratories for studying extreme conditions of pH, metal and metalloid concentrations and bacteria and other organisms that are adapted to these. Metallophyte plants have developed on mine wastes globally; these stabilise the wastes and, if they sequester metals and metalloids in their roots, prevent further accumulation up the food chain by grazers on their roots. The 80 km long AMD Río Tinto, SW Spain, is used as an analogue site for Martian research (18).

Research gaps

Over the past two decades, we have developed a good basic understanding of the environmental impacts and resource potential of mine wastes. There is more to do to better understand the speciation of metals and metalloids, how they are taken up in minerals and biota, the role of microorganisms in their release and storage in the environment, their global health impacts and the ways in which we can recycle, reuse and remediate them. We are now mining ‘green technology’, or ‘critical raw materials’, in much greater quantities than before to meet the demand for a low carbon economy, and there is much work to do to better understand and manage the wastes produced.

References

- Lottermoser, B.G. (2011). Recycling, reuse and rehabilitation of mine wastes. Elements, 7, 405-410.

- Kossoff, D., et al. (2014). Mine tailings dams: Characteristics, failure, environmental impacts, and remediation. Applied Geochemistry, 51, 229-245.

- Nordstrom, D.K. (2011). Mine waters: Acidic to circumneutral. Elements, 7, 393-398.

- Nordstrom, D.K., Blowes, D.W., & Ptacek, C.J. (2015). Hydrogeochemistry and microbiology of mine drainage: An update. Applied Geochemistry, 57, 3-16.

- Sharafi, A., et al. (2018). Environmental geochemistry of near-neutral waters and mineralogy of zinc and lead at the Angouran non-suphide zinc mine, NW Iran. Journal of Geochemical Exploration, 186, 77-93.

- Liu, J., et al. (2018). Ecological patterns and adaptability of bacterial communities in alkaline copper mine drainage. Water Research, 133, 99-109.

- Kossoff, D., et al. (2011). Incongruent weathering of Cd and Zn from mine tailings: A column leaching study. Chemical Geology, 281, 52-71.

- Gleisner, M., & Herbert, R.B. (2002). Sulfide mineral oxidation in freshly processed tailings: Batch experiments. Journal of Geochemical Exploration, 76, 139-153.

- Rytuba, J.J., et al. (2001) Geochemistry of selected mercury mine-tailings in the Parkfield Mercury District, California. USGS Open-File Report 01-336.

- Hudson-Edwards, K.A. (2018). Mining and Planetary Health: A GeoHealth-led special collection. GeoHealth, 2, 278-282.

- Foulds, S.A., et al. (2014). Flood-related contamination in catchments affected by historical metal mining; An unexpected and emerging hazard of climate change. Science of the Total Environment, 476-477, 165-180.

- Macklin, M.G., et al. (2006). Geomorphology, 79, 423-447.

- Bowker, L.N., & Chambers, D.M. (2015). The risk, public liability, & economics of tailings storage facility failures. Report for Bowker Associates Science & Research in the Public Interest. https://www.earthworksaction.org/files/pubs-others/BowkerChambers-RiskPublicLiability_EconomicsOfTailingsStorageFacility%20Failures-23Jul15.pdf (accessed 5 Oct 2020).

- Wates, J., & Götz, A. (2016). Practical considerations in the hyro re-mining of gold tailings. In Gold Ore Processing, 2nd Ed.

- Naidu, G., et al. (2019). A critical review on remediation, reuse, and resource recovery from acid mine drainage. Environmental Pollution 247 1110-1124.

- Lottermoser, B.G. (2010). Mine Wastes: Characterization, Treatment and Environmental Impacts, Third Edition. Springer, Berlin, Heidelberg, 400.

- Gras, A., et al. (2020). Atmospheric carbon sequestration in ultramafic mining residues and impacts on leachate water chemistry at the Dumont Nickel Project, Quebec, Canada. Chemical Geology, 546, 119661.

- Amils, R., et al. (2007). Extreme environments as Mars terrestrial analogs: The Rio Tinto case. Planetary and Space Science, 55, 370-381.