- Home

- About

- Environmental Briefs

-

Distinguished Guest Lectures

- 2023 Water, water, everywhere – is it still safe to drink? The pollution impact on water quality

- 2022 Disposable Attitude: Electronics in the Environment >

- 2019 Radioactive Waste Disposal >

- 2018 Biopollution: Antimicrobial resistance in the environment >

- 2017 Inside the Engine >

- 2016 Geoengineering >

- 2015 Nanomaterials >

- 2014 Plastic debris in the ocean >

- 2013 Rare earths and other scarce metals >

- 2012 Energy, waste and resources >

- 2011 The Nitrogen Cycle – in a fix?

- 2010 Technology and the use of coal

- 2009 The future of water >

- 2008 The Science of Carbon Trading >

- 2007 Environmental chemistry in the Polar Regions >

- 2006 The impact of climate change on air quality >

- 2005 DGL Metals in the environment: estimation, health impacts and toxicology

- 2004 Environmental Chemistry from Space

- Articles, reviews & updates

- Meetings

- Resources

- Index

Reducing e-waste through repair: Slowing the electronics replacement cycle

The Restart Project works to keep electronics in use for longer. This aim is principally achieved through encouraging and supporting repair. The bread and butter has always been ‘Restart Parties’: community events where people teach each other how to repair their broken and slow devices. The project team also

campaigns for electronics to be more fixable and encourages people to choose repair. But, why does Restart think electronics should last longer?

campaigns for electronics to be more fixable and encourages people to choose repair. But, why does Restart think electronics should last longer?

The first answer to that question is because of the rampant problem of electronic waste (e-waste). According to the last estimate conducted by the Global E-waste Monitor around 53 million tonnes of e-waste were produced in 2019 worldwide (1). Such amount outweighs the Great Wall of China and expands each year. E-waste is the fastest

growing waste stream, yet less than 20% of it is recycled globally. We need to get better at recycling e-waste but, more importantly, we simply must throw fewer electronics away.

growing waste stream, yet less than 20% of it is recycled globally. We need to get better at recycling e-waste but, more importantly, we simply must throw fewer electronics away.

|

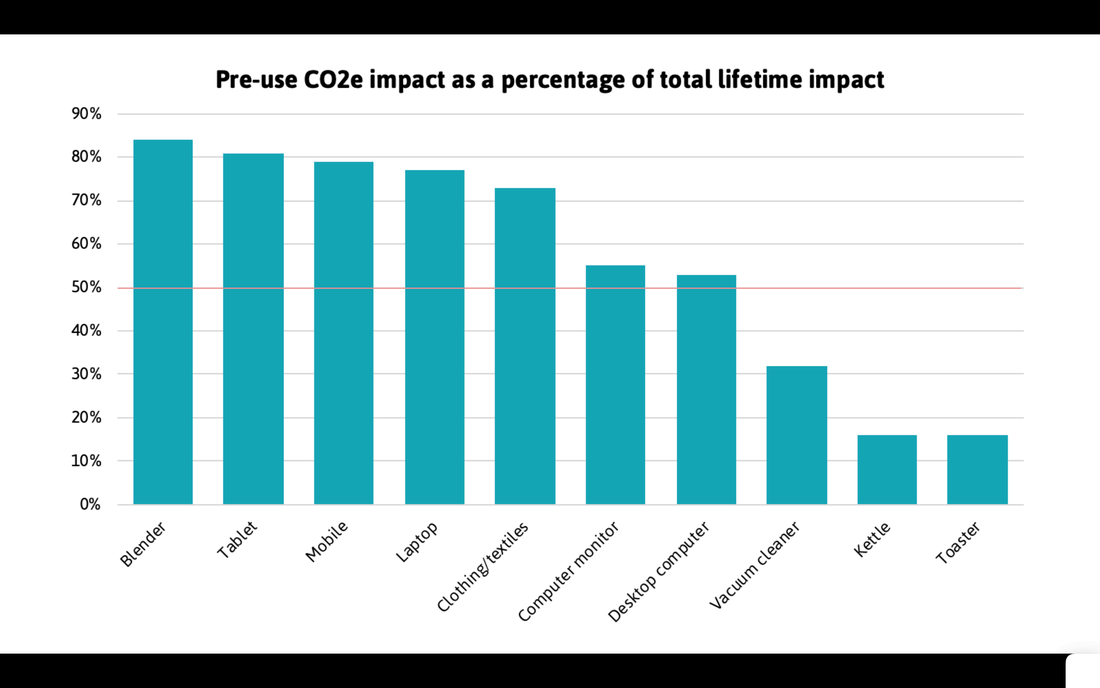

A second and less recognised answer to keep electronics in use for longer is the resources and energy utilised during their production. Last year, the Restart Project looked into the carbon footprint of small electronics from cradle to grave. We reviewed publicly available life cycle assessments conducted by manufacturers, academics, consultancy firms, and public bodies. Information was hard to find. In total we collected data on 1406 products. From these, CO2 equivalent data were extracted on 491 products (2). We found that, for many of the products, most of the global warming impact occurred before we even opened the box; the actual use of our products generates as little as 20% of the carbon emissions produced in their whole lifetimes. This means the best thing we can do to cut the climate impact of electronics is to keep those that we own for as long as possible – and buy fewer new products.

|

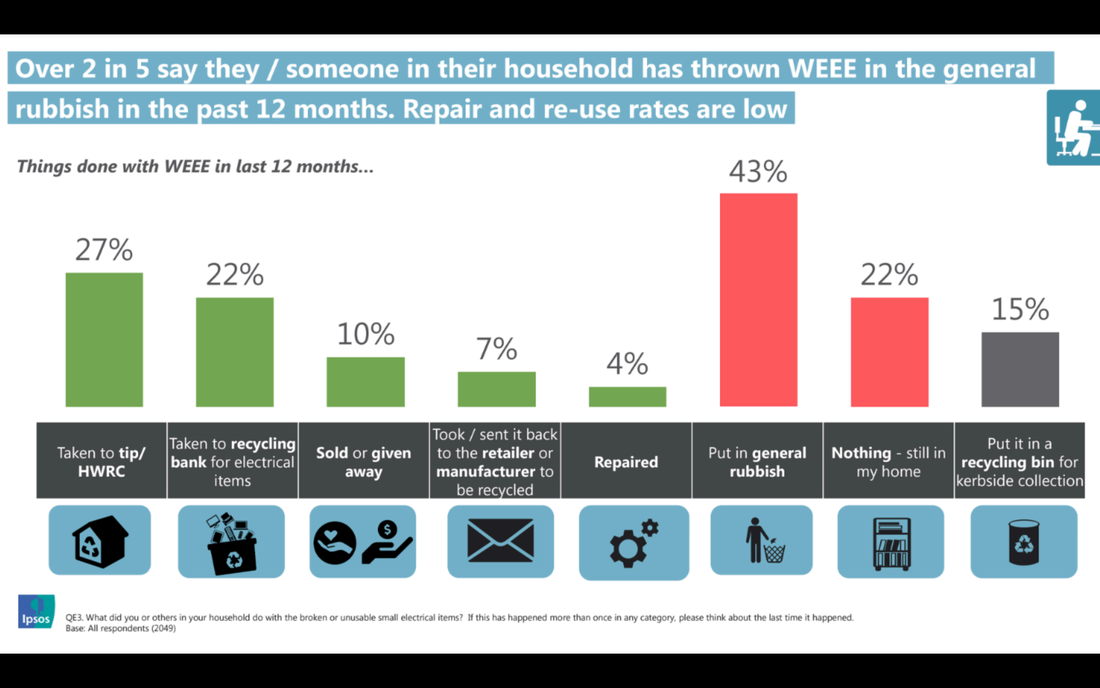

Even repairing a toaster, all environmental indicators considered, scores better than replacing it with a newer, more efficient product. This is considering all common breakdowns until the toaster reaches its expected lifespan of 8 years (3). Whether avoiding waste or reducing emissions, we must slow our replacement cycle, repair more, and use or reuse for longer. The good news is that people like repair: almost 80% of participants across Europe (84% in the UK) said manufacturers should make it easier to repair digital devices (4). Conversely, this opinion does not always translate to behaviour: E-Spares found 75% of people surveyed were more likely to discard broken appliances than attempt to fix them (or is this a product of expectations of the challenges?) (5); Material Focus found that only 4% of people had repaired small electronics, far more kept them at home (22%), recycled them (27%), or put them in general rubbish (43%) (6).

|

So why do more people not repair electronics?

Cost is consistently quoted as a barrier to repair for more than half of people surveyed (7). Spare parts and labour are expensive when compared with cheaper mass produced new products. Professional repair options are harder to find, whilst there are multiple barriers for home repair. Whether intentional or otherwise, electronics are rarely designed for repair. Hardware includes glued components, hidden screws and often requires unique tools for different models. Parts are bundled together so that minor faults require changing several parts. Official repair manuals are hard to source, as are spare parts. Software is also increasingly used to hinder repairs. Most connected products are not supported with security updates for long enough and are increasingly rendered prematurely obsolete. Part pairing is used to tie specific parts to software, ensuring that spare parts can only be sourced from the manufacturer, and must be individually paired to the device by that company. These software barriers to repair are becoming ever more commonplace, not to mention warranties voided, if repairs are carried out by independent shops. |

These built-in barriers mean people are less likely to attempt fixing their own devices; barriers also push up the repair costs for reaching professional service. Hence the vicious cycle of people choosing to replace rather than repair, and repairers going out of business, alongside constant marketing of the newest must-have model.

What can we do to bring back repair? To bring back repair, we must first increase the repair options available to people. The Restart Project’s core work is supporting a network of groups that organises Restart Parties. Based loosely on the repair cafe model, these events provide a space in which people can bring broken and slow devices, and a volunteer repairer will help fix them. But this approach is not simply a free repair service: by involving owners, they overcome the fear of opening electronics and empower people to value the devices they have worked to keep alive.

In 2022, we opened two Fixing Factories in London, and started signposting people. Our Londonrepairs.org directory enables users to find reliable London repair services, and our laptop donation directory points people towards local groups that refurbish devices for donation to those without digital access. Restart is part of a growing ecosystem of people and groups championing repair, but there is much more to do changing perspectives. To really create changes, we need to look upstream at what manufacturers are (or are not) doing to support repair.

A growing movement is calling for a Right to Repair: a right to fix our things without barriers put in place by manufacturers. In 2021, the United Kingdom brought in the first Right to Repair law, which mandated manufacturers to provide spare parts to professional repairers during at least 7 to 10 years for white goods and TVs as well as instruction manuals. But what about all the other electrical products, and community repairers?

There is more progress in the EU Ecodesign legislation, which is where UK Right to Repair law originated pre Brexit. Initially, regulations covered smartphones and tablets, adding laptops, vacuum cleaners, and printers later. By the end of 2024, a recent law will require all phones and tablets sold in the European Union to use the same charger, shrinking the spaghetti of wires and chargers we all have in our homes. Battery legislation is in progress, but movement remains slow and piecemeal. Expected EU consumer rights

legislation that would have introduced more Right to Repair provisions across more products has recently been delayed. If we continue to introduce legislation product by product at this rate, we cannot fix the problem. There are good examples of national pro-repair policies in other countries: a French repair index, which prominently displays a repair score for all electronics at point of sale,

introduced in 2021, is already shifting how consumers buy, and thus impacted manufacturers’ repair offers. An Austrian repair voucher scheme offers 50% off repair costs up to €200. Starting at city and regional level, in 2022, it was rolled out across Austria supported by EU COVID-19 recovery funding. In the United States, appliances with an energy rating may soon require including repair instructions to ship. The challenge is huge, but we have solutions. With infrastructure and public support for repairs growing, manufacturers and governments are being pushed to remove barriers. Let’s look to a future where repair comes first, and e-waste mountains become a thing of the past.

What can we do to bring back repair? To bring back repair, we must first increase the repair options available to people. The Restart Project’s core work is supporting a network of groups that organises Restart Parties. Based loosely on the repair cafe model, these events provide a space in which people can bring broken and slow devices, and a volunteer repairer will help fix them. But this approach is not simply a free repair service: by involving owners, they overcome the fear of opening electronics and empower people to value the devices they have worked to keep alive.

In 2022, we opened two Fixing Factories in London, and started signposting people. Our Londonrepairs.org directory enables users to find reliable London repair services, and our laptop donation directory points people towards local groups that refurbish devices for donation to those without digital access. Restart is part of a growing ecosystem of people and groups championing repair, but there is much more to do changing perspectives. To really create changes, we need to look upstream at what manufacturers are (or are not) doing to support repair.

A growing movement is calling for a Right to Repair: a right to fix our things without barriers put in place by manufacturers. In 2021, the United Kingdom brought in the first Right to Repair law, which mandated manufacturers to provide spare parts to professional repairers during at least 7 to 10 years for white goods and TVs as well as instruction manuals. But what about all the other electrical products, and community repairers?

There is more progress in the EU Ecodesign legislation, which is where UK Right to Repair law originated pre Brexit. Initially, regulations covered smartphones and tablets, adding laptops, vacuum cleaners, and printers later. By the end of 2024, a recent law will require all phones and tablets sold in the European Union to use the same charger, shrinking the spaghetti of wires and chargers we all have in our homes. Battery legislation is in progress, but movement remains slow and piecemeal. Expected EU consumer rights

legislation that would have introduced more Right to Repair provisions across more products has recently been delayed. If we continue to introduce legislation product by product at this rate, we cannot fix the problem. There are good examples of national pro-repair policies in other countries: a French repair index, which prominently displays a repair score for all electronics at point of sale,

introduced in 2021, is already shifting how consumers buy, and thus impacted manufacturers’ repair offers. An Austrian repair voucher scheme offers 50% off repair costs up to €200. Starting at city and regional level, in 2022, it was rolled out across Austria supported by EU COVID-19 recovery funding. In the United States, appliances with an energy rating may soon require including repair instructions to ship. The challenge is huge, but we have solutions. With infrastructure and public support for repairs growing, manufacturers and governments are being pushed to remove barriers. Let’s look to a future where repair comes first, and e-waste mountains become a thing of the past.

References

1. Forti, V., Peters Baldé, C., Kuehr, R., Bel, G. Global e-waste Monitor 2020: The Global E-waste Monitor 2020: Quantities, flows and the circular economy potential. UNU/UNITAR – co-hosted SCYCLE Programme, ITU & ISWA, Bonn/Geneva/Rotterdam, 2020. ISBN Digital: 978-92-808-9114-0 ISBN Print: 978-92-808-9115-7 https://www.itu.int/hub/publication/d-gen e_waste-01-2020/

2. Restart Project 2021. https://therestartproject.org/get involved/ (Accessed 12.01.2023)

3. Bovea, M. D., Ibáñez-Forés, V., & Pérez-Belis, V. (2020). Repair vs. replacement: Selection of the best end-of-life scenario for small household electric and electronic equipment based on life cycle assessment. J. Env. Management, 254, 109679. https://doi.org/10.1016/j.jenvman.2019.109679

4. European Commission: DG Communications Networks Content and Technology, Kantar. Attitudes towards the impact of digitalisation on daily lives. Report, March 2020. Special Eurobarometer (503) European Commission: DG Communication . https://

www.europeansources.info/record/attitudes-towards the-impact-of-digitalisation-on-daily-lives/

5. Dando, T. Survey Suggests UK prefers to replace electronics rather than repair. Resource, 27 August 2019. https://resource.co/article/survey-suggests-uk prefers-replace-electronics-rather-repair (Accessed 12.01.2023)

6. Ipso MORY. Waste Electrical and Electronic Equipment: Public attitudes & behaviours in the UK. Material Focus, January 2021. https://s3.eu-west-1.amazonaws.com/ s3-bucket-recycleyourelectricals.org.uk/wp-content/ uploads/2021/03/WEEE-public-attitudes-and behaviours-original.pdf

7. Nolsoe, E. 45% of smartphone owners would rather upgrade than repair. YouGov, 07 May 2020. https://yougov.co.uk/topics/technology/articles-reports/ 2020/05/07/45-smartphone-owners-would-rather upgrade-repair (Accessed 12.01.2023)

1. Forti, V., Peters Baldé, C., Kuehr, R., Bel, G. Global e-waste Monitor 2020: The Global E-waste Monitor 2020: Quantities, flows and the circular economy potential. UNU/UNITAR – co-hosted SCYCLE Programme, ITU & ISWA, Bonn/Geneva/Rotterdam, 2020. ISBN Digital: 978-92-808-9114-0 ISBN Print: 978-92-808-9115-7 https://www.itu.int/hub/publication/d-gen e_waste-01-2020/

2. Restart Project 2021. https://therestartproject.org/get involved/ (Accessed 12.01.2023)

3. Bovea, M. D., Ibáñez-Forés, V., & Pérez-Belis, V. (2020). Repair vs. replacement: Selection of the best end-of-life scenario for small household electric and electronic equipment based on life cycle assessment. J. Env. Management, 254, 109679. https://doi.org/10.1016/j.jenvman.2019.109679

4. European Commission: DG Communications Networks Content and Technology, Kantar. Attitudes towards the impact of digitalisation on daily lives. Report, March 2020. Special Eurobarometer (503) European Commission: DG Communication . https://

www.europeansources.info/record/attitudes-towards the-impact-of-digitalisation-on-daily-lives/

5. Dando, T. Survey Suggests UK prefers to replace electronics rather than repair. Resource, 27 August 2019. https://resource.co/article/survey-suggests-uk prefers-replace-electronics-rather-repair (Accessed 12.01.2023)

6. Ipso MORY. Waste Electrical and Electronic Equipment: Public attitudes & behaviours in the UK. Material Focus, January 2021. https://s3.eu-west-1.amazonaws.com/ s3-bucket-recycleyourelectricals.org.uk/wp-content/ uploads/2021/03/WEEE-public-attitudes-and behaviours-original.pdf

7. Nolsoe, E. 45% of smartphone owners would rather upgrade than repair. YouGov, 07 May 2020. https://yougov.co.uk/topics/technology/articles-reports/ 2020/05/07/45-smartphone-owners-would-rather upgrade-repair (Accessed 12.01.2023)